Flat Curing Press

A flat curing press, also known as a flatbed vulcanizing press, is a type of hydraulic press used for vulcanizing flat rubber products. It is commonly used in industries such as tire manufacturing, conveyor belt production, and rubber sheet manufacturing.

A flat curing press, also known as a flatbed vulcanizing press, is a type of hydraulic press used for vulcanizing flat rubber products. It is commonly used in industries such as tire manufacturing, conveyor belt production, and rubber sheet manufacturing. Here are some features and functions of a flat curing press:

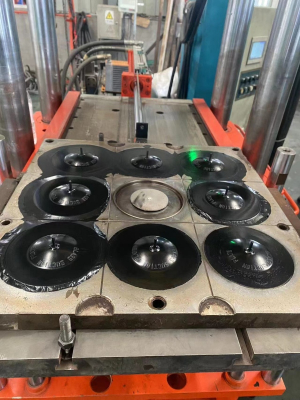

Platen Design: A flat curing press typically has a large, flat platen surface on which the rubber product is placed for vulcanization. The platen is usually made of high-quality steel to provide strength and durability.

Hydraulic System: Like other hydraulic presses, a flat curing press utilizes a hydraulic system to generate the pressure required for the vulcanization process. The hydraulic system includes hydraulic cylinders and a hydraulic power unit that controls the pressure applied to the platens.

Heating System: The platen surfaces of a flat curing press are equipped with heating elements or steam channels to provide the necessary heat for vulcanization. The heating system is designed to maintain a consistent temperature throughout the platens to ensure uniform curing of the rubber product.

Temperature Control: Flat curing presses have temperature control systems, such as digital controllers or thermocouples, to monitor and regulate the temperature during vulcanization. Operators can set the desired temperature and the control system maintains it within a specific range.

Pressure Control: The pressure applied to the platens is adjustable and can be controlled using a pressure control system. Operators can set the required pressure based on the specific rubber material and product being cured.

Safety Features: As with any hydraulic press, flat curing presses are equipped with safety features to protect operators and prevent accidents. These may include emergency stop buttons, safety interlocks, and protective barriers or gates.

Versatility: Flat curing presses come in different sizes and configurations to accommodate various sizes and types of flat rubber products. They can be used for curing rubber sheets, conveyor belts, floor mats, gaskets, and other similar products.

Proper operation, maintenance, and safety procedures should always be followed when using a flat curing press to ensure optimal vulcanization results and operator safety. It is recommended to refer to the manufacturer's guidelines and instructions for specific recommendations on operating the machine.

型号Size | LBL-50F | LBL-100P | LBL-160P | LBL-200P | LBL-200V | LBL-300V |

锁模力(KN) | 500 | 1000 | 1600 | 2000 | 2000 | 3000 |

热板尺寸(mm) | 400x400 | 450x450 | 500x500 | 550x550 | 500x500 | 600x600 |

开模行程(mm) | 300 | 400 | 450 | 500 | 300 | 250 |

最小模厚(mm) | 60 | 60 | 60 | 60 | 50 | 50 |

装机容量(kw) | 12 | 18 | 20 | 20 | 42 | 51 |

机器尺寸(mm) | 1.4x1x1.7 | 2.1x1.8x2.1 | 2x1.9x 2.4 | 2.2x2x3 | 3.4x2.1x2.5 | 3.4x2.6×2.6 |

机器重量(Ton) | 3 | 4 | 4.5 | 5.5 | 10 | 14 |